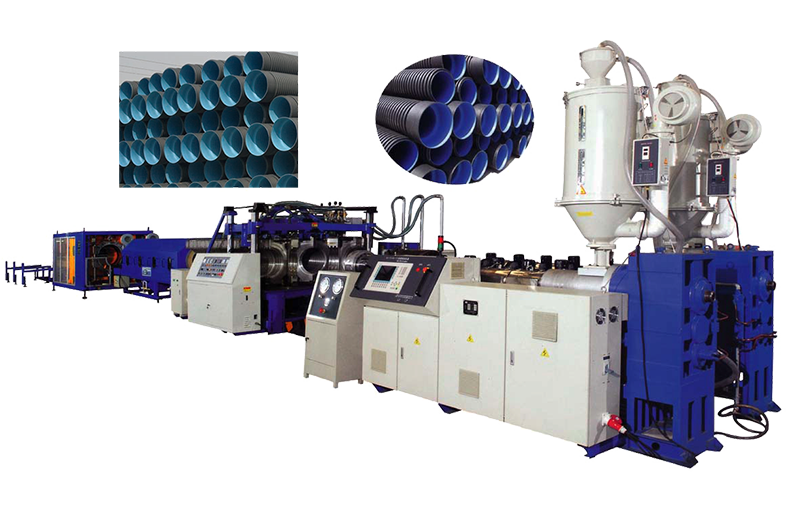

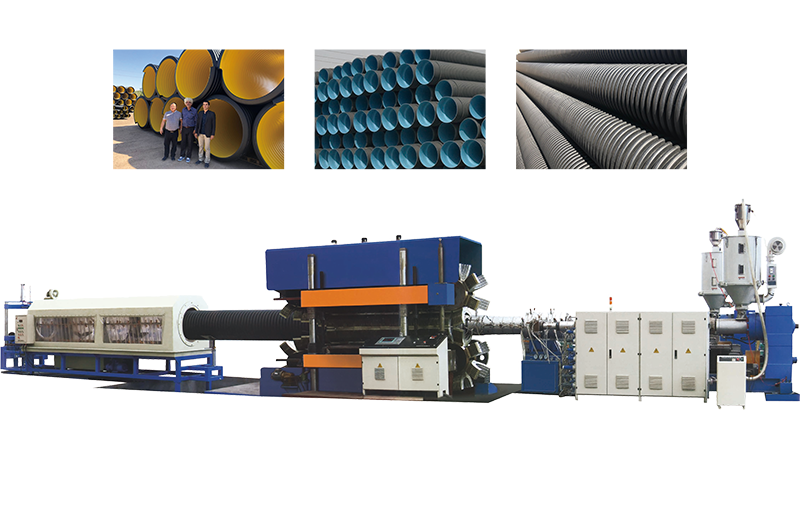

High Speed PE PP (PVC) Corrugated Pipe Extrusion Line

Description

Plastic corrugated pipe machine is used to produce plastic corrugated pipes, which are mainly used in urban drainage, sewage systems, highway projects, farmland water conservancy irrigation projects, and can also be used in chemical mine fluid transportation projects, with a relatively wide range of applications. Corrugated pipe making machine has advantages of high output, stable extrusion and high degree of automation. The extruder can be designed according to the special conditions of user’s material, such as PE PP or PVC. PE PP double-wall corrugated pipe extrusion line use a new type of high-efficiency single/twin screw extruder. PVC corrugated pipe machine use a large flat twin or conical twin extruder. With single layer and two layers for choice. To make double wall corrugated pipes, there are two kinds, horizontal double wall corrugated pipe extrusion line and vertical double wall corrugated pipe extrusion line.

Process Flow

Raw material → Mixing → Vacuum Feeder →Plastic Hopper Drier →Extruder →Extrusion Mold →Forming Mold→ Water cooling Forming machine →Spray Cooling Water Tank →cutting machine →Stacker

Features and Advantages

1. HDPE adopts a new type of high-efficiency single/twin screw extruder, and PVC adopts a large flat twin or conical twin extruder. Big conical twin-screw extruder or parallel twin-screw extruder can realize excellent plasticization at low temperature and stable extrusion.

2. The module cooling method is forced water cooling, which greatly improves the cooling speed of module, so as to achieve high-speed production.

3. The corrugated pipe line also called double wall corrugated pipe machine line can realize on-line flaring to ensure that the various properties of the formed pipe meet the standards.

4. Imported ratio-adjusting valve adjusts forming pressure stable and reliable.

5. Horizontal type corrugator

6. Working plateform is three-dimensionally adjustable.

7. Automatic protection system starts and workable comes back when power off.

8. Automatic lubrication station

9. Mold blocks are made of special aluminum alloy and features light weight, high strength, good wear resistant, small co-efficient of thermal expansion.

10. Air cooling and water cooling for well cooling corrugated molds that forming pipe fast.

11. The corrugated pipe cutting machine has the advantages of high precision and no dust.

12. The complete line adopts PLC micro-computer control system which can visually shows melt temperature and pressure, forming speed, error alarm and also has storage capacity of basic process.

Details

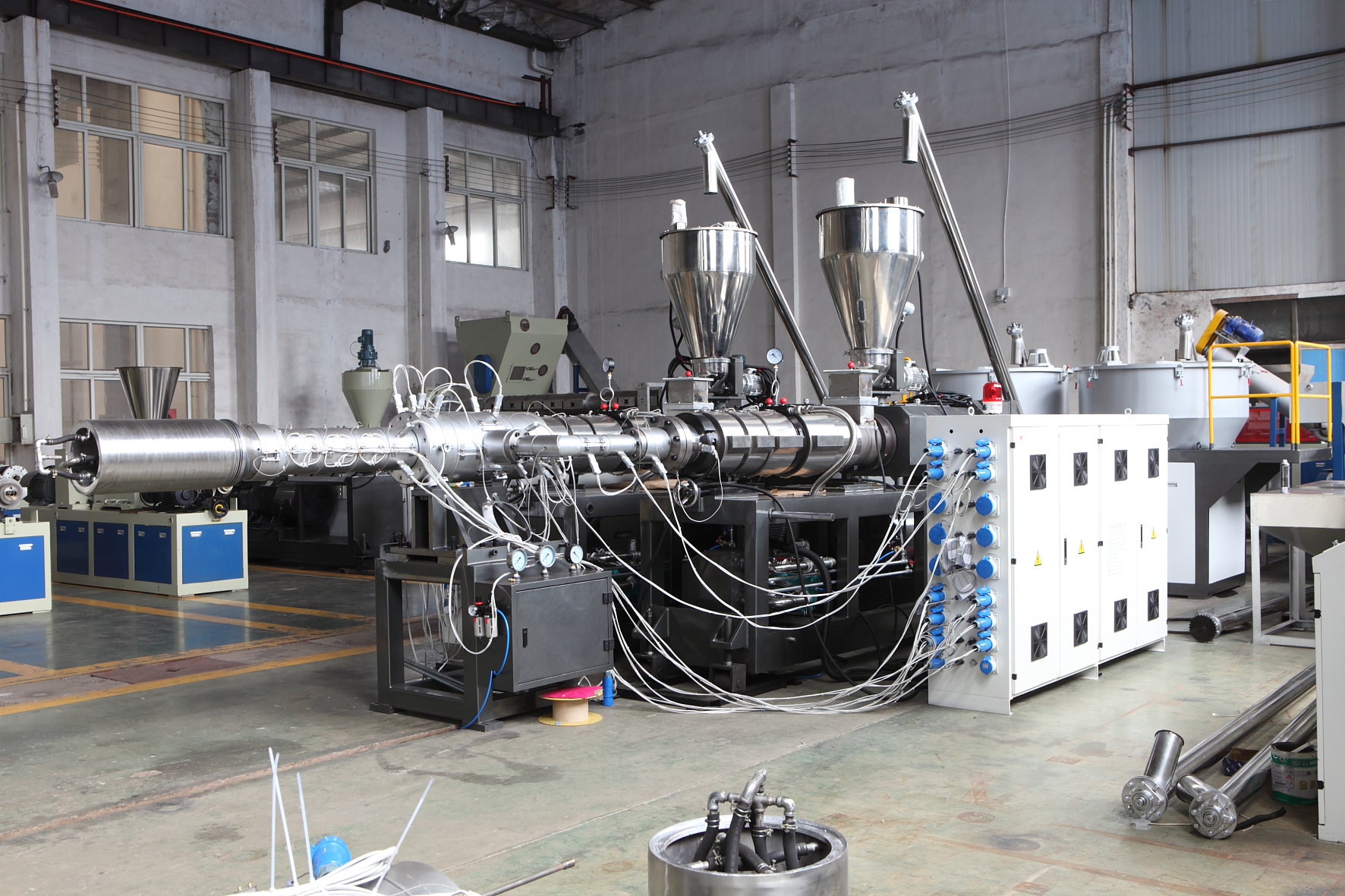

Single Screw Extruder for PE/PP

Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance. Adopt L/D ratio 38:1 screw for virgin material and L/D 33:1 screw for recycled material.

Simens Touch Screen and PLC

Apply program developed by our company, have English or other languages to be input into the system.

Spiral Structure of Barrel

Feeding part of barrel use spiral structure, to ensure material feed in stable and also increase feeding capacity.

Special Design of Screw

Screw is designed with special structure, to ensure good plasticization and mixing. Unmelted material can not pass this part of screw.

Air Cooled Ceramic Heater

Ceramic heater ensure long working life. This design is to increase the area which heater contact with air. To have better air cooling effect.

High Quality Gearbox

Gear accuracy to be ensured 5-6 grade and lower noise below 75dB. Compact structure but with high torque.

Conical Twin Screw Extruder for PVC

Both conical twin screw extruder and parallel twin screw extruder can be applied to produce PVC. With latest technology, to lower power and ensure capacity. According to different formula, we provide different screw design to ensure good plasticizing effect and high capacity.

Extrusion Mold

Both outer layer and inner layer are extruded inside die head. Each material flow channel inside die head is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Also die head provides compressed air between both layer. Calibration sleeve is used to cool inner layer to form smooth and flat pipe inside. Pressure water flows inside calibration sleeve to have good cooling effect. Vacuum is created on calibration sleeve surface when producing big diameter pipe, ensure inner pipe roundness.

Forming Mold

CNC machining ensures accurate dimensions. A vacuum air duct and water-cooling channel with a large flow cross-section ensure stable, high-quality, and efficient production operation. The module material is high-strength aluminum alloy, with high thermal conductivity, high hardness, and high wear resistance. Module structure adopts an integral pressure casting process, with a denser texture and higher thermal stability. The internal surface treatment of the module improves the strength and hardness of the module, which is more conducive to the perfect formation of ripples. The mold adopts CNC machining to ensure its accuracy and smooth operation.

Water cooling Forming machine

Water cooling forming machine is used to place and move corrugated mold, vacuum is created to absorb outer layer into corrugated mould to form corrugate shape. By moving corrugated mold, pipe is also pulled out from corrugator.

Automatic Lubrication System

Automatic lubricate the gears to make corrugated mould moving smoothly.

Transmission Gear Rack

Gear rack is placed at the top of corrugated mould. All gear racks are after nitriding and heating treatment, prolonged wear resisting.

Upper Adjustment System

Electronically adjust upper frame for different size of corrugated mould. With four pillars, ensure stable and accurate adjustment.

Tension Adjusting System

To adjust tensity of mould moving, make mould moving smoothly.

Proportional Valve

To control air more stable and accurate, to form good pipe and socket shape.

Mould Cooling System

With both water cooling and air cooling system, to have better cooling effect, good and fast pipe forming.

UPS Backup Power

When power failure, UPS backup power power will supply power to corrugator to move pipe out from calibration sleeve. To avoid pipe stuck on the calibration sleeve after pipe cooling and shrinkage.

Spray Cooling Water Tank

Cooling tank is used to cool pipe further.

Auxiliary Haul-off

With auxiliary haul off device, also traction device is flexible. To pull pipe further.

Quality Spray Nozzle

Quality spray nozzles have better cooling effect and not easy blocked by impurities.

Water Tank Filter

With filter in the water tank, to avoid any big impurities when outside water comes in.

Corrugated pipe cutting machine

The corrugated pipe cutting machine is high precision and no dust.

Aluminum Clamping Device

Apply aluminum clamping device for different pipe sizes. Each size with it own clamping device, no need to change central central height when for different pipe sizes.

Synchronization system

Cutting station is driven by motor and inverter. During cutting process, cutting station is moving synchronously with corrugator to avoid pipe deformation.

Double Knife Cutting

With two knives cutting together, to ensure end part of socket been fully cut off.

Stacker

To support and unload pipes. Length of stacker can be customized.

To support and unload pipes. Length of stacker can be customized.

In order to move corrugated pipe smoothly on stacker, we apply whole stainless steel on surface of stacker.

To coil pipe into roller, easy for storage and transportation. Usually used for pipe below size 110mm. Have single station and double station for choice.

Technical Data

| Model | Pipe size(mm) | Extruder | Output(kg/h) | Speed(m/min) | Total power(KW) | Mold(pairs) | Cooling system |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Air cooling and water cooling |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Air cooling and water cooling |